1、 Diversion channel

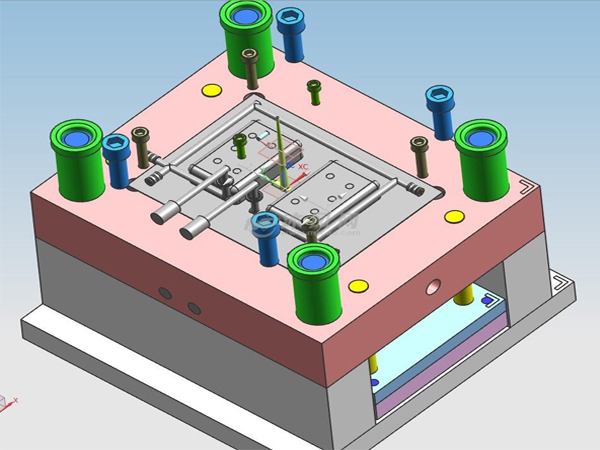

A splitter is a channel in a multi slot mold that connects the gate and each cavity. To ensure that the molten material fills each cavity at an equal speed, the splitter should be arranged symmetrically and equidistantly. In addition, the shape and size of the cross-sectional area of the diversion channel have an impact on the flow of plastic melt, product demolding, and mold manufacturing.

If it is a material with the same flow rate, the channel resistance of the cylindrical section is the smallest. However, the small surface area of the cylindrical flow channel is not conducive to the cooling of the debris in the flow channel, and the flow channel must be set on two half molds, which is both labor-intensive and difficult to align. To solve this problem, relevant personnel will use trapezoidal or semicircular cross-sectional flow channels for mold manufacturing, which are set on the half mold with a demolding rod. The surface of the diversion channel has been polished to reduce flow resistance and provide faster filling speed.

The size of the diversion channel is related to the type of plastic, product size, and product thickness. For most thermoplastic materials, the cross-sectional width of the splitter channel does not exceed 8mm, with oversized ones reaching 10-12mm and particularly small ones ranging from 2-3mm. On the premise of meeting the needs, the cross-sectional area should be minimized as much as possible to extend the cooling time.

2、 Sprue

A gate is a channel that connects the main flow channel (or diversion channel) to the mold cavity. The cross-sectional area of the gate is less than or equal to the cross-sectional area of the sprue or runner. The gate is the smallest part of the entire channel system, and its shape and size have a significant impact on the quality of the product.

The gate has a great effect on controlling the material flow speed and preventing the backflow of early-setting molten material. When the passing molten material is subjected to strong shear and increases temperature, the gate can reduce the apparent viscosity to improve flowability and facilitate the separation of the product and the flow channel system.

Why should the size design of the gate consider the properties of the plastic melt? The shape, size, and position of the gate are closely related to the properties of the plastic, and the cross-sectional shape of the gate is generally rectangular or circular. In addition, the gate position should be the thickest part of the product without affecting its appearance.

3、 Cavity

The cavity is the space in the mold where plastic products are formed, and the components used to form the cavity are collectively referred to as forming parts. The formed parts that form the appearance of the product are called concave molds, also known as female molds; The formed parts that form the internal shape of a product are called cores or convex molds, also known as male molds.

The design of formed parts needs to consider the performance of plastic, the geometric shape of the product, dimensional tolerances, and usage technology.